Category: Ferro Alloys

Ferro Alloys

Showing 49–61 of 61 results

-

Silicon-aluminum-ferro alloy is a deoxidizer used in steelmaking production to improve the shape of inclusions and reduce the content of gas elements in molten steel. It is an effective new technology to improve steel quality, reduce costs, and save aluminum. For the production of silicon-aluminum-ferro alloys, there are two types of raw material processing methods: …

-

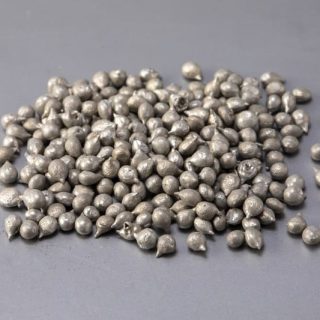

Silicon briquette is made of silicon slag powder by machine-press, and silicon slag is the by-product of silicon metal. It contains Si from 40% to 70%.Silicon carbon briquette also contains high content of C besides of Si, which is widely used to raise the furnace temperature.Silicon briquette have the same physical and chemical properties as …

-

Silicon carbide is made of silicon sand, coke, wood and other raw materials by resistance furnace smelting at high temperature.Silicon carbide has a stable chemical composition, with anti-wear, anti-corrosion, high temperature, impact resistance, good thermal conduction and other advantages.

-

Silicon carbon alloy, also known as high carbon silicon or high carbon ferro silicon, is a kind of by-product of silicon metal, it contains Si(60-70%) with C(15-25%). Silicon carbon alloy usually is used to replace the ferro silicon in steel plant.

-

Silicon slag is a mixture containing 40% to 90% of the main content of silicon and is a by-product of silicon metal. It is a good substitute for ferro silicon in steel making which has advantage in reducing cost. Size: 0-3mm, 1-10mm, 10-50mm or as per customers’ requirement. Packing:1MT/bag mainly used in steelmaking. The silicon …

-

Silicon-calcium alloy is a composite alloy composed of silicon, calcium and iron. It is an ideal composite deoxidizer and desulphurizer. Silicon Alloy not only has strong deoxidation ability, deoxidation products are easy to float and discharge, but also can improve the properties of steel, improve the plasticity, impact toughness and fluidity of steel. At present, …

-

tin (Sn), a chemical element belonging to the carbon family, Group 14 (IVa) of the periodic table. It is a soft, silvery white metal with a bluish tinge, known to the ancients in bronze, an alloy with copper. Tin is widely used for plating steel cans used as food containers, in metals used for bearings, …

-

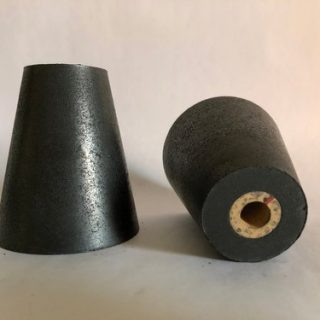

Tundish nozzle is an important part of continuous casting production.Molten steel flows from the tundish into the crystallizer through the tundish nozzle.In this process, the outlet hole will be eroded and widened, the amount of molten steel in unit time will increase, and the surface of molten steel in the mold will increase, so it …

-

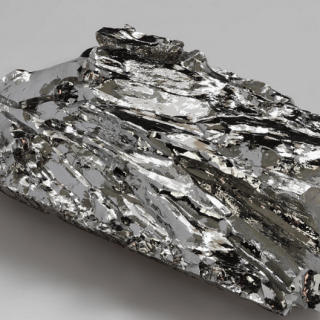

Tungsten is a lustrous and silvery white metal. The bulk metal resists attack by oxygen, acids and alkalis. Tungsten has the highest melting point of any metal. Applications Tungsten is used in filaments in incandescent light bulbs, it is also used in electric contacts and arc-welding electrodes. Tungsten is used in alloys, such as steel, …

-

Uraninite, a major ore mineral of uranium, uranium dioxide (UO2). Uraninite usually forms black, gray, or brown crystals that are moderately hard and generally opaque. A variety of uraninite ore that is dense and found in granular masses with a greasy lustre is called pitchblende. Uraninite is radioactive and is the chief source of uranium.

-

Ferroalloy refers to various alloys of iron with a high proportion of one or more other elements such as manganese, aluminium, or silicon. They are used in the production of steels and alloys.

-

Zirconium is a very strong, malleable, ductile, lustrous silver-gray metal. Its chemical and physical properties are similar to those of titanium. Zirconium is extremely resistant to heat and corrosion. Zirconium is lighter than steel and its hardness is similar to copper. When it is finely divided, the metal can spontaneously ignite in air, especially at …